Previous tree caps used in the industry generally required specific radial alignment of the cap to ensure proper insertion and secure placement in the subsea tree. Achieving a particular radial alignment is difficult when installing a tree cap with an ROV.

The design advantage of the Aker Subsea tree cap is that an ROV can install it into a subsea tree at any rotational orientation.

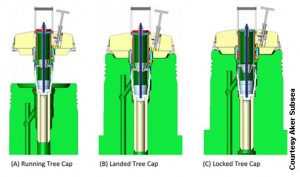

The tree cap has a primary and secondary locking mechanism actuated by hydraulic pressure to lock into the subsea tree and to set the metal seals. To prevent any damage to the metal seals during installation, the tree cap lands and locks into the tree by the primary locking mechanism prior to setting the metal seals.

The primary mechanism is activated when hydraulic pressure applied into the cavity moves a piston downward, which causes the upper set of locking dogs to move outward into the locking profile of the subsea tree. This selectively locks the tree cap into the tree.

The secondary lock mechanism consisting of a cam, rod, and spring method then sets and secures the metal seals, which are designed to isolate the annulus and production bores of the tree. Hydraulic pressure continues to force the seal carrier downward, which allows the cam and rod to move downward. This permits the lower sets of dogs to engage, thus securing the seal carrier with both metal seals into the designated position. The metal seals are tested and qualified to a working pressure of 15,000 psi and a temperature range of 0?250 °F.

The Aker Subsea tree cap includes a mechanism that indicates whether the metal seals have been accurately set within the seal bore of the tree, and the design also permits testing of the metal seals after installation. The tree cap is rated for deepwater applications up to 10,000 ft depth, with a working pressure of 10,000 psi and an operating system pressure of 3,000 psi.

To counter the problem of fluid becoming trapped between the cavity of the tree cap and the subsea tree, which would prevent the cap from properly landing into position, the design includes a flow path and valve which removes the water. The tree cap allows corrosion inhibitor to be injected into the cavity between the tree and cap and into the bores above the annulus and production valves.

To learn more about Aker Subsea’s subsea products and services, visit the Aker Solutions subsea website.

楊寶劍 是振威(全球)石油網的高級技術編輯,在石油技術資訊行業有八年的學識和經驗。他源源不斷地提供石油行業全球最新的技術創新、研發成果、現場應用情況等信息。如果你對“新技術新產品”的內容有任何問題或建議,請聯系楊寶劍編輯 +86 10-58236512 Email:allenyo@zhenweiexpo.com 歡迎您提供手中的最新技術文章!